联系人:茅经理 电话:13056831999 邮箱:yunyimagnet@163.com

◎ 钕铁硼磁铁介绍

▪ 钕铁硼磁铁是稀土永磁材料中性能表现较为突出的磁体。 其是由金属钕、铁、硼和其他微量元素构成并通过粉末冶金工艺制作而成的的合金磁体。钕铁硼磁铁具有高剩磁、高矫顽力和极高的磁能积,性价比高。并具有非常好的机械加工性能。所以钕铁硼磁铁被称为磁王。

▪ 钕铁硼磁铁表面抗氧化和抗腐蚀的能力较差,所以在通常情况下表面需要做电镀处理。鑫盛永磁科技的电镀种类有磷化、金、银、锌、镍铜镍、环氧树脂等等。我司的电镀均符合欧盟的ROHS要求。

▪ 钕铁硼磁铁是第三代稀土永磁。其中的主要成分稀土金属在我国的储量十分丰富,我国稀土磁铁的产量占世界生产总量的70%-80%左右。在激烈的市场竞争条件下,鑫盛永磁科技有限公司主要针对高端的电机、电声、医疗器械等领域的客人,不断探索,持续研发,目前我司的产品性能可以达到世界同行专业的水平。

◎ 工艺流程

配料-熔炼-制粉-压制-烧结-性能检测-机械加工-表面电镀-检验-包装充磁-交货-售后服务

◎ 常规牌号

| 系列 | 牌号 | 剩磁(Br) | 内禀矫顽力(Hcj) | 矫顽力(Hcb) | 最大磁能积(BH)max | 密度ρ | 回复 磁导率 μrec |

温度系数(α) | 最高工作温度 | |||||||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | αBr | αHcj | ℃(L/D=0.7) | |||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | %/℃ | %/℃ | ||||

| N | N30 | 1.13 | 1.08 | 11.3 | 10.8 | 955 | 12 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 1.05 | -0.12 | -0.76 | 80 |

| N33 | 1.17 | 1.13 | 11.7 | 11.3 | 955 | 12 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N35 | 1.22 | 1.17 | 12.2 | 11.7 | 955 | 12 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N38 | 1.25 | 1.22 | 12.5 | 12.2 | 955 | 12 | 860 | 10.8 | 310 | 287 | 39 | 36 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N40 | 1.28 | 1.25 | 12.8 | 12.5 | 955 | 12 | 860 | 10.8 | 326 | 302 | 41 | 38 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N42 | 1.32 | 1.28 | 13.2 | 12.8 | 955 | 12 | 860 | 10.8 | 342 | 318 | 43 | 40 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N45 | 1.37 | 1.32 | 13.7 | 13.2 | 955 | 12 | 860 | 10.8 | 366 | 342 | 46 | 43 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N48 | 1.43 | 1.37 | 14.3 | 13.7 | 955 | 12 | 860 | 10.8 | 390 | 358 | 49 | 45 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N50 | 1.44 | 1.39 | 14.4 | 13.9 | 955 | 12 | 860 | 10.8 | 406 | 374 | 51 | 47 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N52 | 1.46 | 1.42 | 14.6 | 14.2 | 955 | 12 | 836 | 10.5 | 422 | 390 | 53 | 49 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N54 | 1.49 | 1.45 | 14.9 | 14.5 | 955 | 12 | 836 | 10.5 | 437 | 406 | 55 | 51 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| N56 | 1.51 | 1.47 | 15.1 | 14.7 | 876 | 11 | 836 | 10.5 | 454 | 414 | 57 | 52 | 7.5 | 1.05 | -0.12 | -0.76 | 80 | |

| M | 30M | 1.13 | 1.08 | 11.3 | 10.8 | 1114 | 14 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 1.05 | -0.12 | -0.68 | 100 |

| 33M | 1.17 | 1.13 | 11.7 | 11.3 | 1114 | 14 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 35M | 1.22 | 1.17 | 12.2 | 11.7 | 1114 | 14 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 38M | 1.25 | 1.22 | 12.5 | 12.2 | 1114 | 14 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 40M | 1.28 | 1.25 | 12.8 | 12.5 | 1114 | 14 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 42M | 1.32 | 1.28 | 13.2 | 12.8 | 1114 | 14 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 45M | 1.37 | 1.32 | 13.7 | 13.2 | 1114 | 14 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 48M | 1.42 | 1.37 | 14.2 | 13.7 | 1114 | 14 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 50M | 1.44 | 1.39 | 14.4 | 13.9 | 1114 | 14 | 1035 | 13 | 406 | 374 | 51 | 47 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 52M | 1.46 | 1.42 | 14.6 | 14.2 | 1114 | 14 | 1035 | 13 | 422 | 382 | 53 | 48 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 54M | 1.49 | 1.44 | 14.9 | 14.4 | 1114 | 14 | 1035 | 13 | 438 | 398 | 55 | 50 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| 56M | 1.5 | 1.46 | 15 | 14.6 | 1035 | 14 | 995 | 12.5 | 446 | 406 | 56 | 51 | 7.5 | 1.05 | -0.12 | -0.68 | 100 | |

| H | 30H | 1.13 | 1.08 | 11.3 | 10.8 | 1353 | 17 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 1.05 | -0.12 | -0.66 | 120 |

| 33H | 1.17 | 1.13 | 11.7 | 11.3 | 1353 | 17 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 35H | 1.22 | 1.17 | 12.2 | 11.7 | 1353 | 17 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 38H | 1.25 | 1.22 | 12.5 | 12.2 | 1353 | 17 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 40H | 1.28 | 1.25 | 12.8 | 12.5 | 1353 | 17 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 42H | 1.32 | 1.28 | 13.2 | 12.8 | 1353 | 17 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 45H | 1.37 | 1.32 | 13.7 | 13.2 | 1353 | 17 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 48H | 1.42 | 1.36 | 14.2 | 13.6 | 1353 | 17 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| 52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1059 | 13.3 | 422 | 382 | 53 | 48 | 7.5 | 1.05 | -0.12 | -0.66 | 120 | |

| SH | 30SH | 1.13 | 1.08 | 11.3 | 10.8 | 1592 | 20 | 804 | 10.1 | 247 | 223 | 31 | 28 | 7.4 | 1.04 | -0.115 | -0.56 | 150 |

| 33SH | 1.17 | 1.13 | 11.7 | 11.3 | 1592 | 20 | 844 | 10.6 | 271 | 247 | 34 | 31 | 7.4 | 1.04 | -0.115 | -0.56 | 150 | |

| 35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 876 | 11 | 287 | 263 | 36 | 33 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 939 | 11.8 | 326 | 302 | 41 | 38 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 48SH | 1.4 | 1.36 | 14 | 13.6 | 1592 | 20 | 1035 | 13 | 390 | 358 | 49 | 45 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| 50SH | 1.42 | 1.39 | 14.2 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 1.04 | -0.115 | -0.56 | 150 | |

| UH | 30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 1.03 | -0.11 | -0.5 | 180 |

| 33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| 35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| 38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| 40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| 42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| 45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 1.03 | -0.11 | -0.5 | 180 | |

| EH | 30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.6 | 1.03 | -0.1 | -0.45 | 200 |

| 33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.6 | 1.03 | -0.1 | -0.45 | 200 | |

| 35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 1.03 | -0.1 | -0.45 | 200 | |

| 38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 1.03 | -0.1 | -0.45 | 200 | |

| 40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.6 | 1.03 | -0.1 | -0.45 | 200 | |

| 42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.6 | 1.03 | -0.1 | -0.45 | 200 | |

| AH | 28AH | 1.09 | 1.02 | 10.9 | 10.2 | 2786 | 35 | 772 | 9.7 | 231 | 199 | 29 | 25 | 7.6 | 1.03 | -0.1 | -0.45 | 230 |

| 30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.6 | 1.03 | -0.1 | -0.45 | 230 | |

| 33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.6 | 1.03 | -0.1 | -0.45 | 230 | |

| 35AH | 1.2 | 1.17 | 12 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 1.03 | -0.1 | -0.45 | 230 | |

| 38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 1.03 | -0.1 | -0.45 | 230 | |

备注:计算温度系数的温度区间划分为:SH档及以下,ΔT:20-100℃;SH档及以上,ΔT:20-150℃,温度系数仅作参考,详细退磁曲线请和我们销售人员联系。

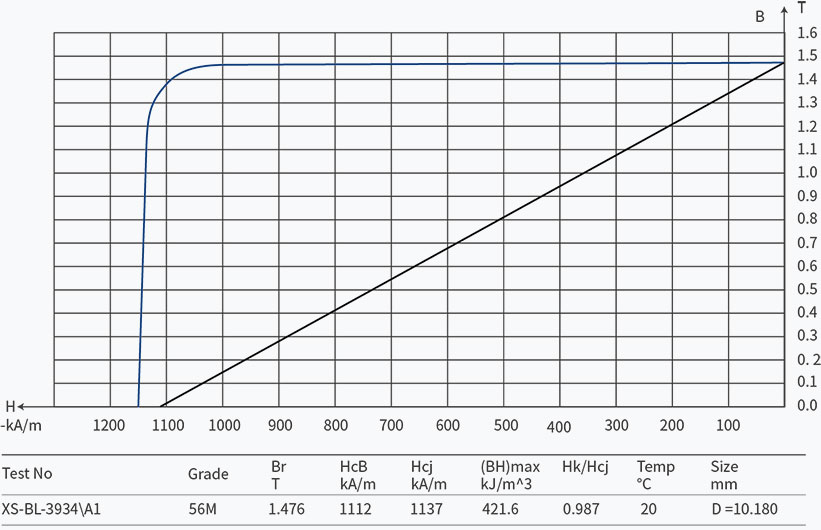

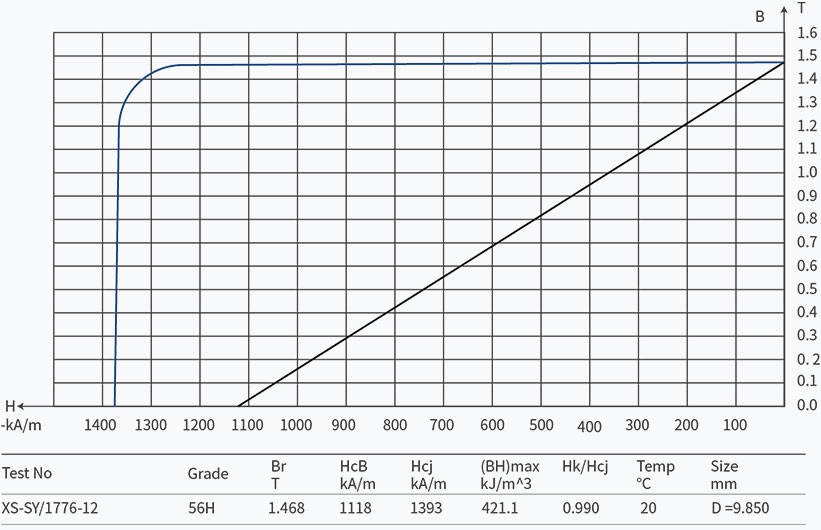

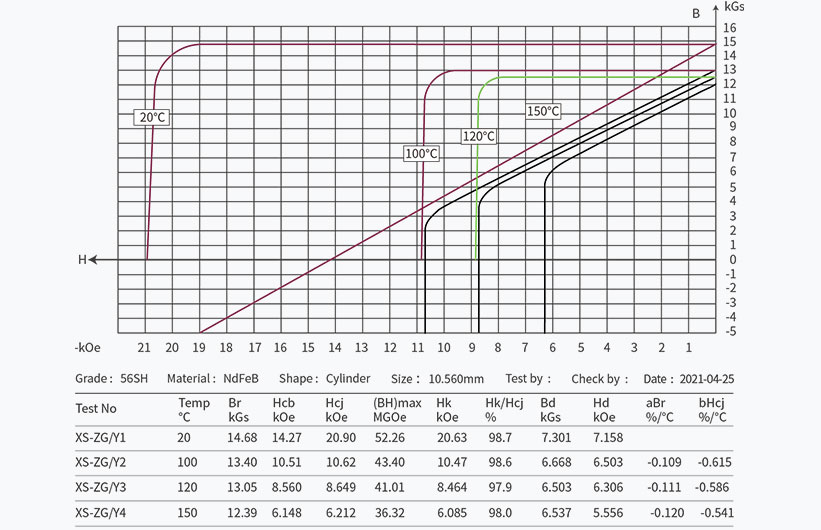

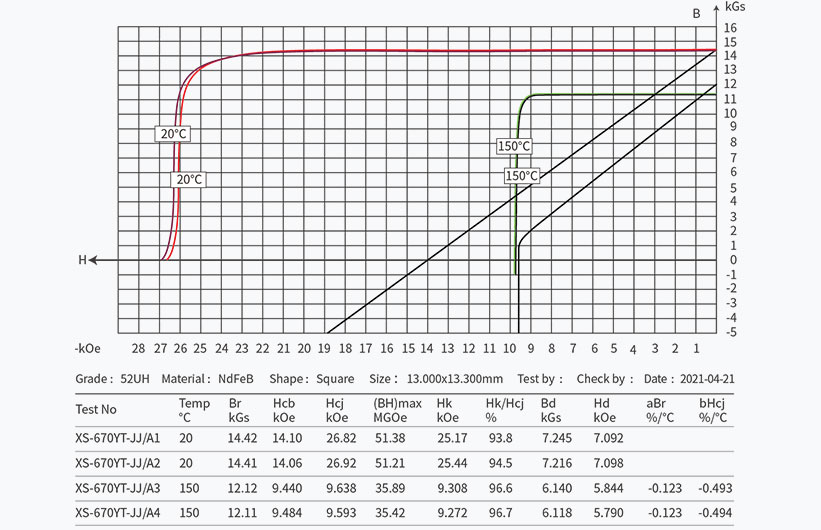

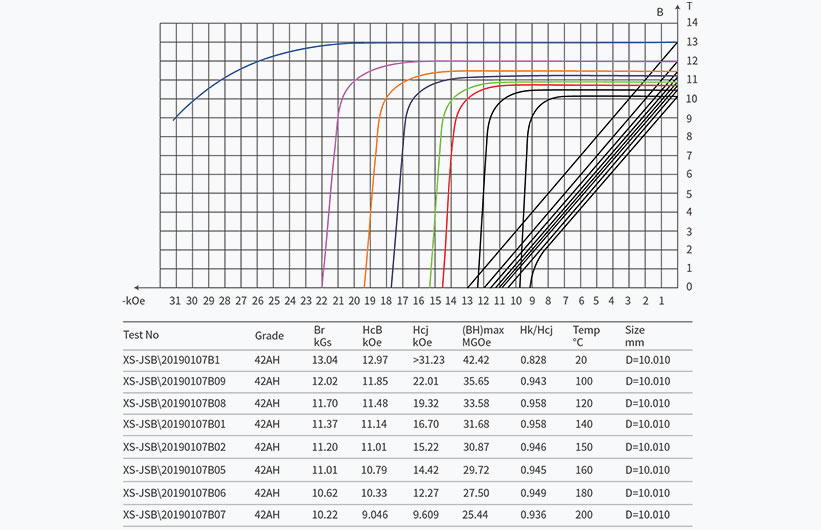

◎ 退磁曲线

56M

56H

52SH

56SH

52UH

54UH

48EH

42AH